Hanwha HM520 Chip Mounter

Patch speed: 80,000 CPH

size:890x2370x1930mm

weight:1605KG

Product description: Hanwha HM520 modular pick and place machine, it's Hanwha's first modular chip mounter, 890MM length.Patch speed: 80,000 CPH,Spindle head, size:890x2370x1930mm,weight:1605KG

Hanwha HM520 Pick and Place Machine

Hanwha HM520 Pick and Place Machine

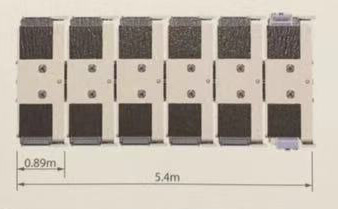

Hanwha HM520 modular Pick and Place Machine, it's Hanwha's first modular chip mounter, 890MM length.

890MM length ultra-small Chip mounter

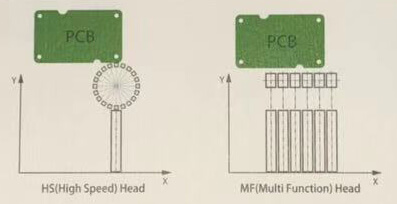

80,000CPH(Rotary Head)

60,000 CPH (Piano Head)

LED products: 72,000 CPH (Rotary)

Automatic detection of pick and placing problem.

Automatically replenishing suction/mounting position and height deviation

Preventing LED defects caused by turning

PCB: Max (L) 750x (W) 580mm (optional)

Equipment size:2370x1440x890mm

Power AC200 / 208/220/240/380

Equipment weight:1605KG

The Hanwha HM520 modular Pick and Place Machine is a high-speed Modular Chip Mounter equipped with Rotary Head.

high-performance newer flying camera placement machine that delivers world-class top speeds of 80,000 CPH .

03015Chip ~ 14mm can be basically corresponding, and through the application of high-speed.

High-precision electric feeder, improve the actual productivity and placement quality.

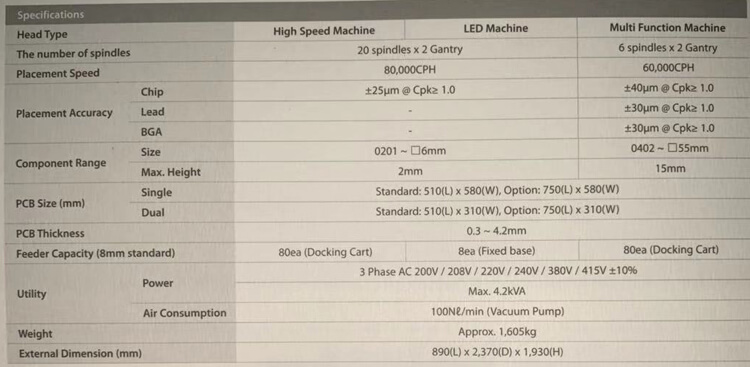

Hanwha HM520 Chip Mounter parameters

Number of shafts: 10 shafts * 2 cantilever

Mounting Speed: 80000CPH (Rotary Head Conditions)

Mounting accuracy: 1μm

Component Size: 03015, BGA, CSP (Ball Pitch 0.03mm)

Electrically Driven High Speed and High Accuracy.

High Productivity

20 Spindle Head:

Design to small and light head So that can use Fix Camera to identify 20 Spindle one times.

Fix Camera High clear High Pixel:

Use high clear(5M) camera, Can pick and place Mini LED chip, Mobile phone micro chip(0402,0603) in high speed.

HM Feeder(8mm):

New design 8mm HM feeder, successly shorted 24% pick and place time.

Optimized LED production:

By Adapting Rotary head, reached 74000CPH real production speed with a few HM feeders.

Enlarged Erea Productivity:

Enlarged PCB production size(L750mm), Shrinked equipment length(W0.89M), Highly enlarged unit erea's productivity.(40% more than Decan Series Pick and Place Machine).

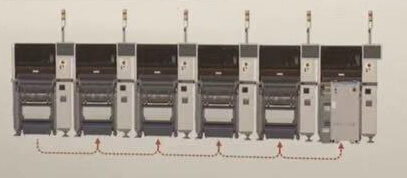

Reduce Cycletime by share Badmark information:

Share badmark informations identified by first equipment with other equipment in the SMT assembly line, Reduced cycletime by share these badmark informations.

High Reliability

Side View Camera, Prevent missing components:

Check nozzle status and components status duiring production process, checking before place component on PCB and after place component on PCB to prevent component miss placing problem. And check the component height in real time and automatic correct component position on PCB to prevent bad component placing.

Automatic correct picking and placing position:

Use the COR data from Calibration result to correct pick and place position to prevent placing mistake.

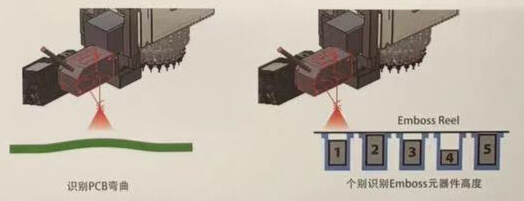

Height Sensor:

Can pick Emboss components without teaching by use Height Sensor, Automatic correct placing position tollerence caused by curved PCB.

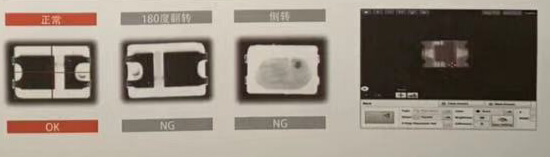

LED components invert checking function:

Checking component invert or not by Vision Camera to prevent bad component placing on PCB.

Keywords:

Hanwha SM481 PLUS Pick and Place Machine, Hanwha SM482 PLUS Pick and Place Machine, Hanwha SM471 PLUS Pick and Place Machine, Hanwha Decan S2 Pick and Place Machine, JUKI RS-1R Pick and Place Machine, DEK NeoHorizon 03ix SMT Stencil Printer, JUKI RS-1R SMT Assembly Line, Hanwha SM481 Plus SMT Assembly Line.

Contact:Tommy

Phone:+8613691605420

E-mail:tommy@qersa.com

Address:94# Guangtian Road Yanluo Baoan District Shenzhen