Working width: 45-516 mm

Process length: 4,840 mm

Heated length: 3,725 mm

Cooling length: 1,115 mm

Weight appr. 1,900 kg

Dimension: 6,265x1,201x1,375 mm

Ersa HOTFLOW 3/20e SMT Reflow Oven

Ersa HOTFLOW 3/20e SMT Reflow Oven

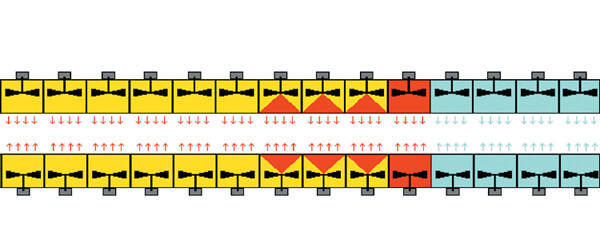

Dual track transport increases throughput

Optimized heat transfer, minimized ΔT zone

Separation

Internal cooling

Lowest energy consumption

Removable heating modules top and bottom

Extreme low-mass center support

ERSASOFT Process Data Recorder

ERSASOFT – user-friendly machine control

Auto profiler for rapid offline profiling

Ersa HOTFLOW 3/20e Reflow Oven

The Ersa HOTFLOW 3/20e Reflow System is of robust design and qersa.com manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Dimensions

Length: 6,265 mm

Width: 1,201 mm

Height: 1,375 mm

Weight appr. 1,900 kg

Conveyor system

Working width: 45-516 mm automatically infinitely adjustable

Clear passage height: +35/-37 mm

Center support, automatically infinitely adjustable

Conveyor speed: 20-200 cm/min

Pin-and-chain conveyor with either 3 / 4 / 5 mm pin length

Process zone

Process length: 4,840 mm

Heated length: 3,725 mm

Cooling length: 1,115 mm

Heating system

Up to 20 convection heating cassettes

(Preheat zone up to 14 cassettes, reflow zone 6 cassettes)

Volumetric flow rate each module, adjustable, up to 500 m3/h

Rated power each module: 3.3 kW

Rated power last module: 4.5 kW

Cooling

Up to 2 level cooling zone (ambient air)

Electrical data

400 V, 3 Phase, N, Ground, 50/60 Hz

Continuous output during operation: appr. 12-16 kW

Exhaust

Extraction capacity: stack at entry of system 300 m3/h; stack at exit of system 400 m3/h, both with monitoring feature

Options:

Pin-and-chain conveyor with low-mass center support

Automatic adjustment of the conveyor width and the center support

Up to 2 tracks with center supports possible in the system

For single track systems, low-mass tubular supports are available

Operating in ambient atmosphere, internal cooling with room air

RPMs of fan motors are adjustable via frequency converters

Pin-and-chain conveyor 3 / 4 / 5 mm pin length

Keywords:

Hanwha SM481 PLUS Pick and Place Machine, Hanwha SM482 PLUS Pick and Place Machine, Hanwha SM471 PLUS Pick and Place Machine, Hanwha Decan S2 Pick and Place Machine, JUKI RS-1R Pick and Place Machine, DEK NeoHorizon 03ix SMT Stencil Printer, JUKI RS-1R SMT Assembly Line, Hanwha SM481 Plus SMT Assembly Line.

Contact:Tommy

Phone:+8613691605420

E-mail:tommy@qersa.com

Address:94# Guangtian Road Yanluo Baoan District Shenzhen