Working width: 45-560 mm

Process Length: 3,260 mm

Length Heated: 1,525 mm

Length Cooled: 1,735 mm

Weight app. 1,100 kg

Dimension: 3,905x1,410x1,350 mm

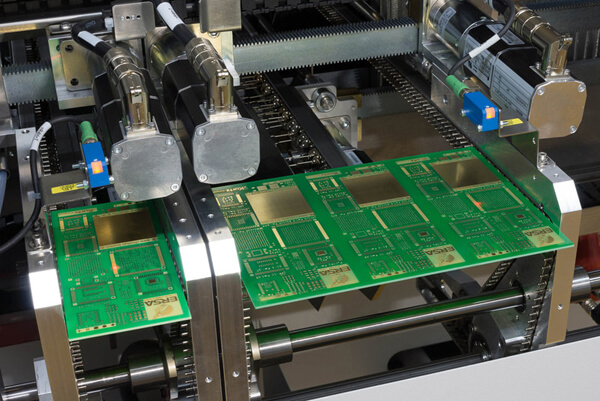

Ersa HOTFLOW 4/8 Reflow Oven

High performing compact reflow system

Multi-stage cooling, both internal and external

Efficient process gas cleaning system

Low N2 consumption

Auto Profiler for quick profile generation

Multi-track conveyor system available

Thermally invisible center supports

Low energy consumption in continuous operation

Process control software Ersa Process Control (EPC)

Patented grip-conveyor system for flex circuits

Energy-usage optimized fan motors with integrated frequency converters

Ersa HOTFLOW 4/8 Reflow Oven

The Ersa HOTFLOW 4/08 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process qersa.com gas cleaning and a powerful and effective cooling zone.

Dimensions

Length: 3,905 mm

Width: 1,410 mm

Height: 1,350 mm

Weight app. 1,100 kg

Conveyor system

Working width: 45-560 mm, infinitely, automatically adjustable

Clear passage height: +32/-40 mm

Center support, infinitely, automatically adjustable

Conveyor speed: 20-200 cm/min

Pin-and-chain conveyor with 3 / 4 / 5 mm pin length

Process zone

Process Length: 3,260 mm

Length Heated: 1,525 mm

Length Cooled: 1,735 mm

Heating system

Convection heating modules, 8 units in total

(Preheating up to 6 units, reflow zone 2 units)

Volumetric flow rate each module adjustable up to 500 m3/h

Rated power each module: 3.3 kW

Cooling

3 level cooling zone with water back cooling

Electrical data

400 V, 3 Phasen, N, P, 50/60 Hz

Continuous output during operation: appr. 6-8 kW

Exhaust

Extraction capacity 2 stacks each 300-600 m3/h, monitored

Options:

Pin-and-chain conveyors 3 / 4 / 5 mm pin length

Pin-and-chain conveyors with low-mass center supports

Automatic width adjustment of conveyors and low-mass center supports

Up to 2 tracks with low-mass center supports in system

Patented grip conveyor system for flex boards

For an oven with single track, low-mass tubular supports are available

Operation possible with either ambient air or with nitrogen atmosphere

Cooling available with either integrated or external cooling unit

Cooling with either cooling unit or with local cold water connectio

Keywords:

Hanwha SM481 PLUS Pick and Place Machine, Hanwha SM482 PLUS Pick and Place Machine, Hanwha SM471 PLUS Pick and Place Machine, Hanwha Decan S2 Pick and Place Machine, JUKI RS-1R Pick and Place Machine, DEK NeoHorizon 03ix SMT Stencil Printer, JUKI RS-1R SMT Assembly Line, Hanwha SM481 Plus SMT Assembly Line, Hanwha Decan S2 Assembly Line.

Contact:Tommy

Phone:+8613691605420

E-mail:tommy@qersa.com

Address:94# Guangtian Road Yanluo Baoan District Shenzhen